At Alexander Battery Technologies we have seen a rapid rise in the levels of demand our customers have for creating an E-Mobility application. From Skateboards to Electric Vehicles (EVs), we have seen original equipment manufacturers (OEMs) of all sizes gravitate towards their applications being powered by battery packs. In this article, we will explore why there has been an uptake in E-Mobility and why OEMs are choosing Alexander Battery Technologies to design & manufacture custom battery packs for their E-Mobility projects.

Market Trends

The latest figures, in the UK, reveal that sales of EVs rose 60% from April 2022 to April 2023, this rise in Pure electric represents 15.78% of newly registered vehicles compared to the 8.02% that are diesel. These figures have been made possible by governments bringing in measures to make owning an EV as beneficial as possible. Whether through generous tax breaks to both businesses and consumers or the governments, themselves putting more resources into their own charging infrastructure, owning an electric vehicle has never been more beneficial to the consumer. Stricter emission regulations have been implemented to tackle the ongoing climate crisis across the European Union in a bid to reduce greenhouse gas emissions and combat climate change. As a result, automakers are required to reduce the average CO2 emissions of their fleets.

Consumer Awareness

Like many businesses across the world, consumers themselves are taking measures to decrease their carbon footprint. Switching from fossil fuel-powered vehicles to cleaner electric-powered vehicles is both an easy and efficient way to decrease a consumer’s carbon footprint. One of the most obvious factors in the rise of EVs is cost. Latest figures reveal the value of three-year-old EVs plunged by up to 30.7% compared to what they were worth the previous year. The price drop and consumer confidence in the quality of a three-year-old EV battery pack have led to increased EV ownership.

Investment in Technological Advancements

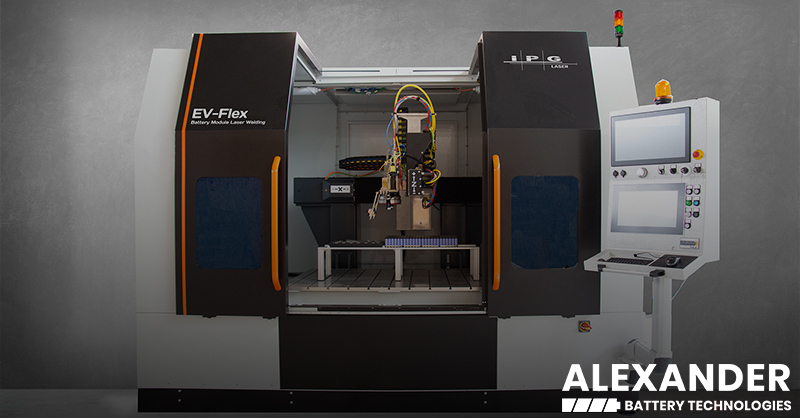

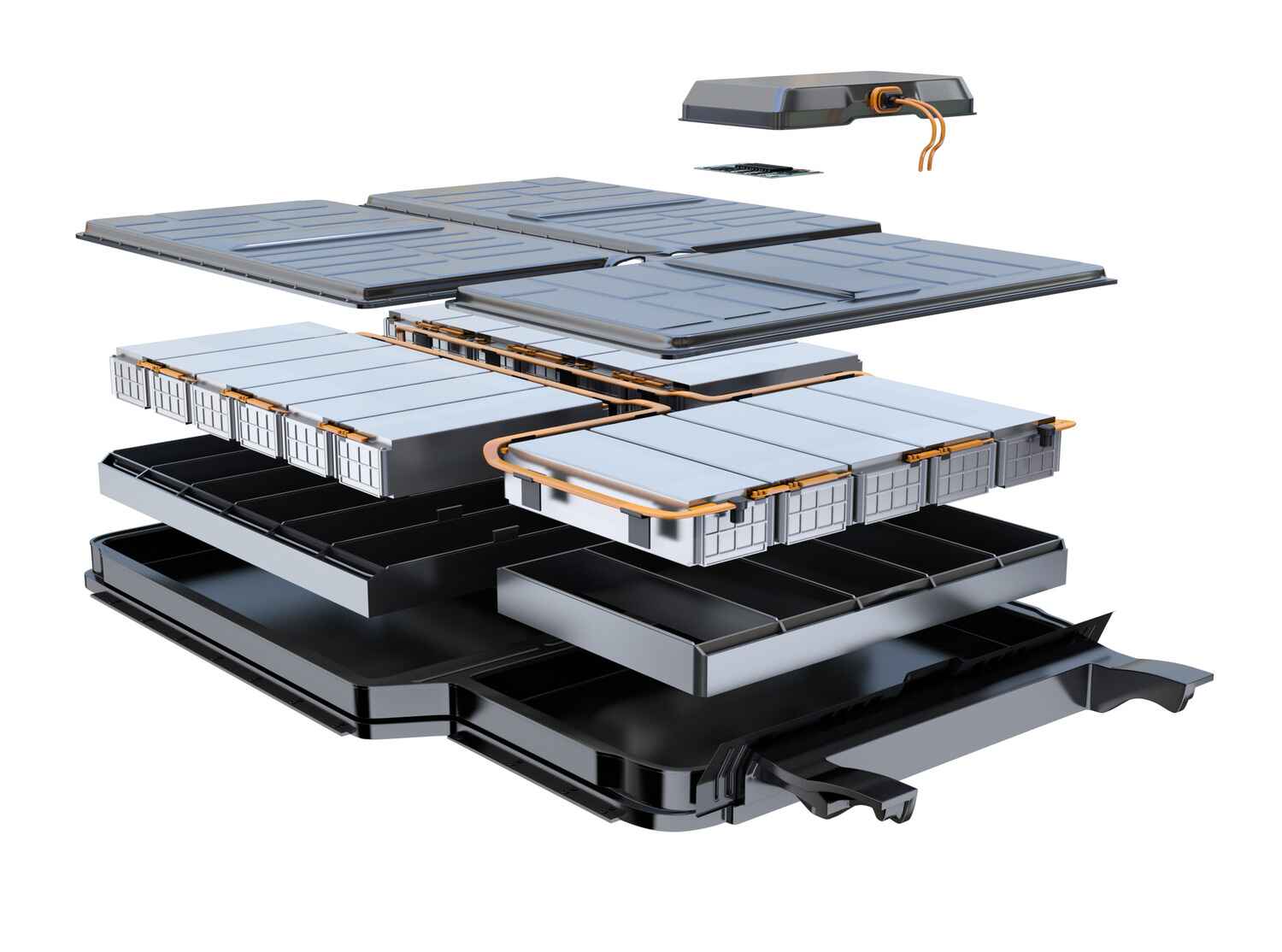

Alongside the previously mentioned price drop, there has been significant investment in technological advancements and facilities to manufacture high-quality battery packs used in EVs. The development of our own Battery Technology Centre (BTC) is a great example of this. From our market-leading Battery Technology Centre and UK manufacturing facility, we conceive and manufacture innovative product solutions, delivering each project on time and on budget to a global client base. In the BTC, you will find specialist research and development labs that have been built with the goal to develop the highest quality battery pack possible. For an E-Mobility project, this means designing a battery pack that’s; fast charging and robust whilst maintaining power through their longer life cycles. The opening of the BTC has given us the capability to manufacture these newly developed custom battery packs that will power pure electric vehicles.

Our Manufacturing Capabilities

In such a fast-moving industry like E-Mobility, battery manufacturers and OEMs know having short lead times is crucial to a products success in the market. OEMs recognise the capability that Alexander Battery Technologies have in being fast-to-market. This is all built from having a rapid new product introduction (NPI) at the start of every project. Whilst accommodating the priorities and specifications of our customers we have the ability to deliver a bespoke custom-made battery pack prototype just five weeks after an initial introduction call. This allows customers the ability to provide any feedback necessary to tweak the battery pack before we manufacture it. Should the customer choose to go ahead with the project we have the ability to increase our production very quickly. We aim to have $2 million of free stock at all times to significantly speed up our production. This ramp-up allows us to reach our capacity of producing 100,000 packs a week to ensure OEMs can be fast to market with their application.

What we can provide E-Mobility OEMs

OEMs recognise that part of the attraction of working with Alexander Battery Technologies on an E-mobility project is the high-quality level of in-house expertise we bring to their project. As Alexander Battery Technologies only manufactures bespoke custom battery packs and chargers, our engineering team can design a battery pack that will meet any required certification. Our expertise can be seen throughout all of our departments, end-of-line tests happen in certified labs to ensure any imperfections that happen in the manufacturing process have been identified before being sent to our customers. As a result, we provide reliable and durable battery packs to power any E-Mobility applications.

Conclusion

With our newly found manufacturing capabilities being backed by over 40 years of custom battery pack design and manufacturing experience, OEMs are turning to Alexander Battery Technologies to power their application in a rapidly developing market.

Should you need any help with your custom battery pack projects, please complete the contact us form.

4 mins Read

4 mins Read  16/06/2023

16/06/2023