The first cargo bike boom happened in the 1930s and 40s where they were primarily used to quickly transport goods to aid war efforts. Nearly 100 years later cargo bikes have seen a resurgence for largely the same reasons, this time the cargo bikes are electrified. E-cargo bikes are being invested in heavily due to being a more sustainable and a faster way to transport goods around major cities than their alternatives. This, on top of increasing pressure on many countries around the world, especially in the EU, to cut their carbon footprint has seen the second boom of cargo bikes.

Growth in the electric cargo bike market

The E-Cargo bike market saw its first real spike in growth from 2019 into 2020. This initial rise in growth was due to the environmentally friendly benefits provided, alongside battery technology having the capability to meet an OEMs usage requirement. Between 2022 and 2030 the industry is forecasted to have a compound annual growth rate (CAGR) of 20% to 6 billion USD in 2030.

The increasing number of online orders needing to be delivered to big cities has seen an increase in delivery hubs. Lorries are great for transporting packages to these hubs, but delivery companies needed an efficient last-mile delivery solution to perfect their entire delivery system. Delivery vans were initially thought to be an efficient solution due to the number of packages they could carry. However, in practice, E-cargo bikes were found to be a better solution in large cities due to their rechargeable nature and the speed in which they can navigate busy streets. This realisation has seen large delivery companies switch their efforts to rechargeable E-cargo bikes to make their last-mile delivery fleet quicker and as a way to reduce their carbon footprint.

What is causing this level of growth

This growth has been caused by governments looking to reduce their carbon footprints. The UK has set a target to achieve net zero by 2050, part of this plan has seen Transport for London (TFL) announce plans to promote and enable the growth of e-cargo bikes. TFL has estimated this will save 30,000 tonnes of carbon emissions within London. Reductions in emissions in London will see major cities across the world join the e-cargo bike revolution.

Amazon has made at least 5 million deliveries from their e-cargo bike hub based in central London as they increase their effort to wipe out diesel vans from their delivery fleets. On top of their environmental benefits, e-cargo bikes also allow the rider to navigate busy cities more efficiently than they would in a van. They also have a significant cost saving attached to them, being cheaper to run than alternative fossil-fuelled transport.

Battery pack requirements for e-cargo bikes

Due to how e-cargo bikes are used determines how we engineer the battery pack for optimal performance. Most E-cargo bikes will be used by for last-mile delivery services and therefore be kept at a logistic hub. At logistics hubs, there will be lots of battery packs available for the rider to plug directly into their E-cargo bike and head out with a fresh charge. This modular way of powering a fleet of vehicles ensures the riders will have a bank of battery packs available to them to keep them delivering as long as they need to.

For this reason, we will make sure the battery pack is fast charging and will be able to go through a high amount of charge cycles. This will be achievable via the fully integrated BMS (battery management system) we put into all of our packs. To ensure riders get to their destination in a timely manner, the battery pack will need to have high discharge capabilities whilst being in an ultra-lightweight robust pack to limit the weight the battery pack is powering. The battery pack will also need to meet UL2271 certification in order to be sold in the United States. We also need to ensure each pack is made with a consistently high quality so riders don’t experience a drop of in performance when switching out their battery packs regularly.

For all these needs to be met within the tight space requirements that an e-cargo bike offers, a bespoke custom battery pack will be best for an OEM (original equipment manufacturer). Our expert engineers have experience in designing battery packs with the necessary requirements to fit your application. We can integrate a smart BMS within your battery pack to ensure its performance and health is properly managed.

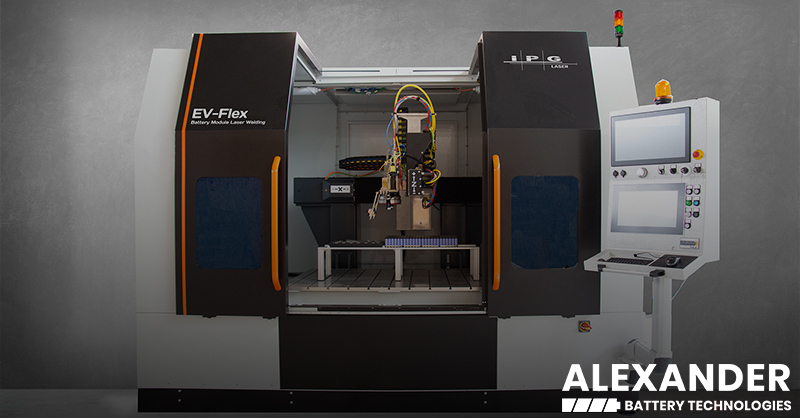

Our Manufacturing Capabilities

In a fast-moving market such as e-cargo bikes, short lead times are crucial to a products success. OEMs recognise the capability that Alexander Battery Technologies have in being fast-to-market. This is all built from having a rapid new product introduction (NPI) at the start of every project. Whilst accommodating the priorities and specifications of our customers we have the ability to deliver a bespoke custom-made battery pack prototype just five weeks after an initial introduction call. This allows customers the ability to provide any feedback necessary to tweak the battery pack before we manufacture it. We have rapid ramp-up capabilities that allow us to manufacture 100,000 packs a week. We put a strong emphasis on sustainability in every part of our manufacturing process.

What we can provide E-cargo bike OEMs

We provide OEMs a European manufacturing hub in a newly built state-of-the-art battery technology centre. OEMs recognise that part of the attraction of working with Alexander Battery Technologies on an e-cargo bike project is the high-quality level of in-house expertise we offer. We only manufactures bespoke custom battery packs and chargers, our engineering team can design a battery pack that will meet any required certification. Our expertise can be seen throughout all of our departments, end-of-line tests happen in certified labs to ensure any imperfections that happen in the manufacturing process have been identified before being sent to our customers.

With our newly found manufacturing capabilities being backed by over 40 years of custom battery pack design and manufacturing experience, OEMs are turning to Alexander Battery Technologies to power their application in a rapidly developing market. Should you need any help with your custom battery pack projects, please complete the contact us form.

6 mins Read

6 mins Read  29/11/2023

29/11/2023