A manufacturing company is aiming to become a £100m turnover business by 2026 after investing almost £2m in new machinery and equipment.

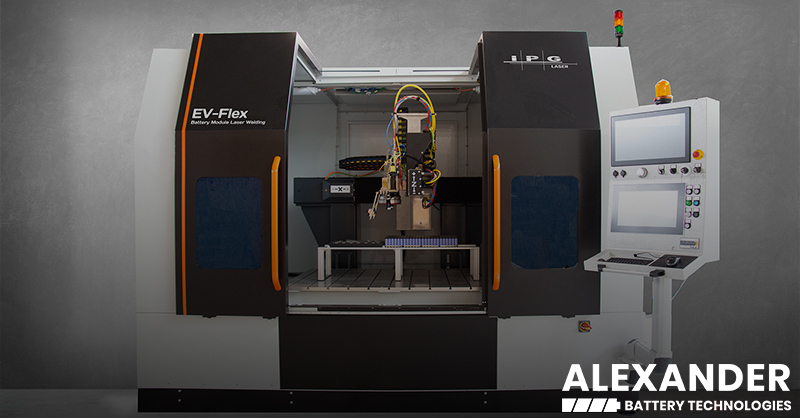

Peterlee-based Alexander Battery Technologies, which manufactures customisable battery packs and chargers, has converted two 20,000 sq. ft buildings into a state-of-the-art production facility and a warehouse. The business also leases another 16,000 sq. ft facility which it is planning to convert into a world-class R&D facility. The investment committed by the company has been supported by a six-figure grant from the County Durham Growth Fund.

The grant has supported the addition of an Electrostatic Discharge (ESD) production area, the purchase of a 3D printer, an engineering and production lab for the creation and testing of products and a production flow to allow for flexible manufacturing of various products. It has also allowed Alexander Battery Technologies to create training areas for staff, improved facilities such as a larger canteen, an expanded designated maintenance area and significantly increased manufacturing space to accommodate the growing workforce which has risen to 110 people.

More importantly, the investment has significantly increased production capacity –it has allowed the company to increase capacity by 500 per cent and is now capable of manufacturing up to 100,000 packs in a single shift weekly.

Managing director Mark Rutherford said: “The investment committed by the company and the grant from the County Durham Growth Fund has really boosted our ability to secure work with blue-chip companies – their approval process is very intensive and requires a world-class operational footprint to become an approved supplier.

“Now our facilities are real selling points and we’re very proud of them, so we want people to come and visit to see what we can offer. This is not something we have been able to do in the past due to our dated facility and manufacturing techniques.

“The investment has made the business world-class, and we are now able to attract staff from market leaders in the automotive and rail industries. That’s testament to where we are as a company and crucially, where we want to get to which is to become a £100m turnover company in the next four years.” Mark and fellow director Claire Brymer, supported by an experienced senior management team, have set out a three-phased growth plan.

The first phase is the optimisation of the company’s sales and marketing strategy, which includes filling the factory with contracts for the medical, test and measurement, and military sectors among others. Phase two will see the expansion of the R&D facility at Unit 4, which will support the organic growth of the business through new business and additional work from existing clients. The final phase is to support the growth of Alexander Battery Technologies into Europe, targeting OEMs (Original Equipment Manufacturers) and securing multi-million-pound contracts with them. This will be the phase of growth which sees the business reach £100m turnover. Claire Brymer said: “It is such an exciting time for the business and the investment committed over the last couple of years has put us in an incredibly strong position, enabling us to put in place a hugely ambitious strategy for growth which will put us on the global map.”

Karen McParlin from Business Durham said: “It’s fantastic to see businesses like Alexander Battery Technologies embarking on such a transformational growth journey. This investment has taken the business from one that was very much operating behind the scenes to one which is standing loud and proud, with world-class facilities that the very biggest of brands will want to utilise.”

Simon Allen, Investment Centre Director at UMi, said “I attended the investment panel meeting where Alexander Battery Technologies’ application was approved, and the panel members were so impressed with the ambition shown by the leadership team. They knew their plans were not without risk, however, they had signalled their commitment to significant investment which they believed could take the business to one with a global reputation. Now, it’s clear to see that the capital investment and the grant awarded by the County Durham Growth Fund panel has paid off – the facilities really are world-class.”

The County Durham Growth Fund is managed by Business Durham in partnership with UMi and is supported by the European Regional Development Fund (ERDF). All successful grant applications are appraised by UNW LLP, an independent firm of chartered accountants and business advisers.

Neville Bearpark, UNW’s Head of Grant Support Services, added: “Alexander Battery Technologies is the perfect example to showcase what the County Durham Growth Fund was set up to do – taking a business with local roots and helping it implement plans which will see it become a global business with turnover upwards of £100m.”

4 mins Read

4 mins Read  20/06/2022

20/06/2022